Materials: steel, leather, wood, fabric, cushion

Height: 37"

Width: 24.5"

Depth: 26"

Weight: 27 lbs

Collapsed Volume: 2.8 cu. ft.

Assembly/Disassembly Time: 1 minute

In Cirque, I wanted to create a chair that played with the ideas of form and movement. Through sketches and brainstorming, Dumbo, the circus elephant, became the metaphor for my chair. My intention was to work with movement and a balance of light and heaviness, like Dumbo flying. The chair's collapsibility and transportability also fit nicely in this metaphor as Dumbo worked at a traveling circus.

Left: Mood Board for Cirque

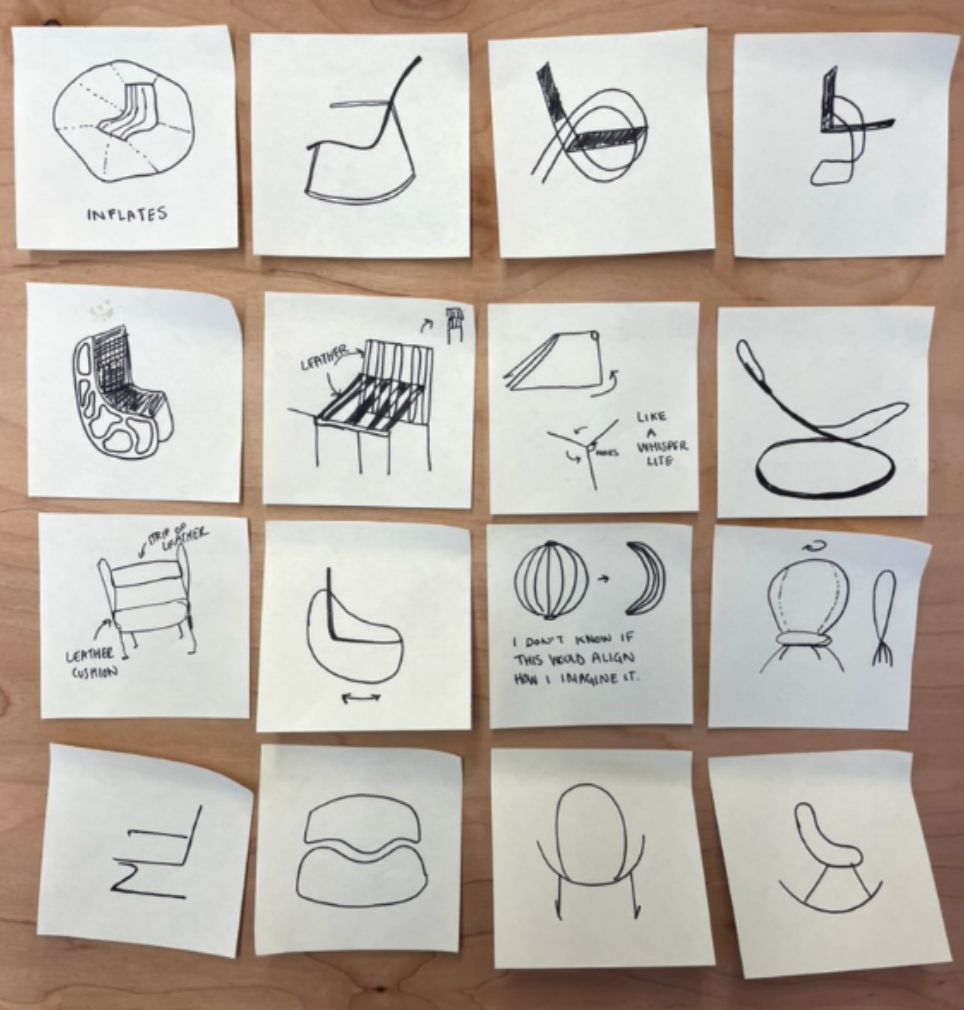

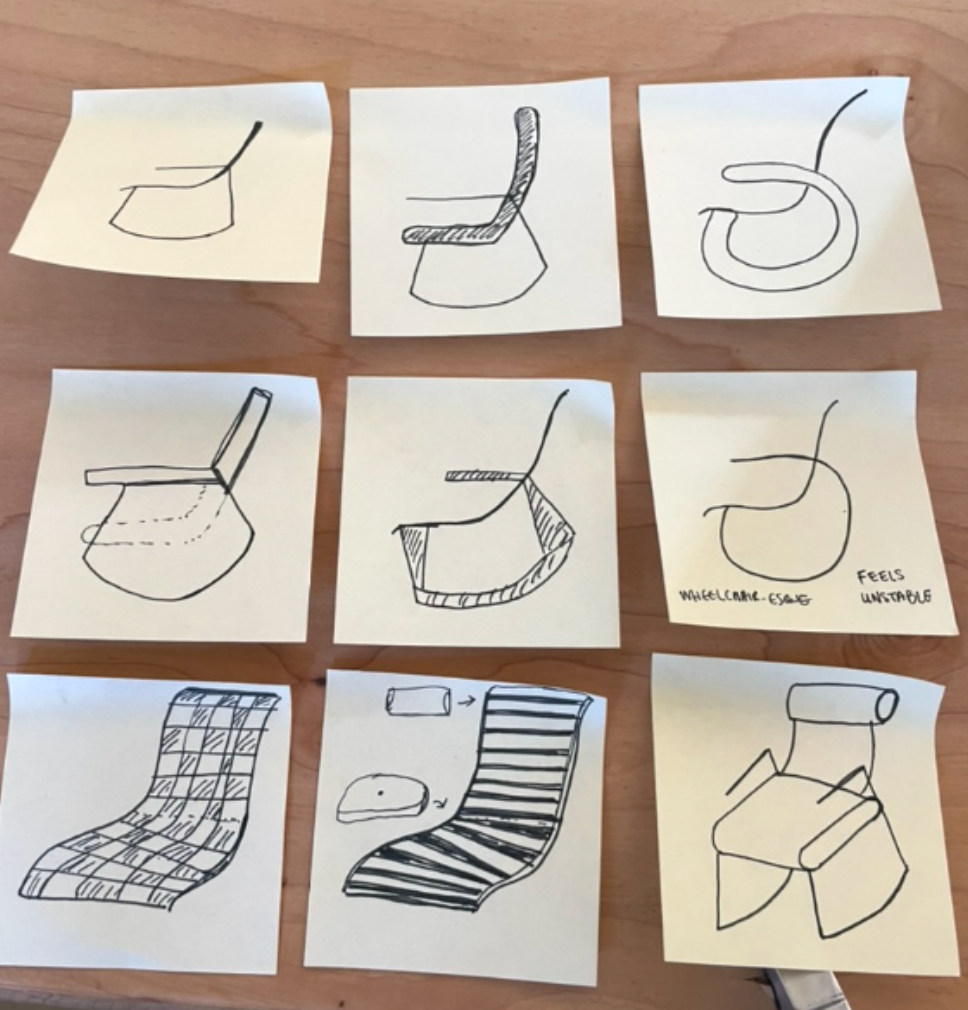

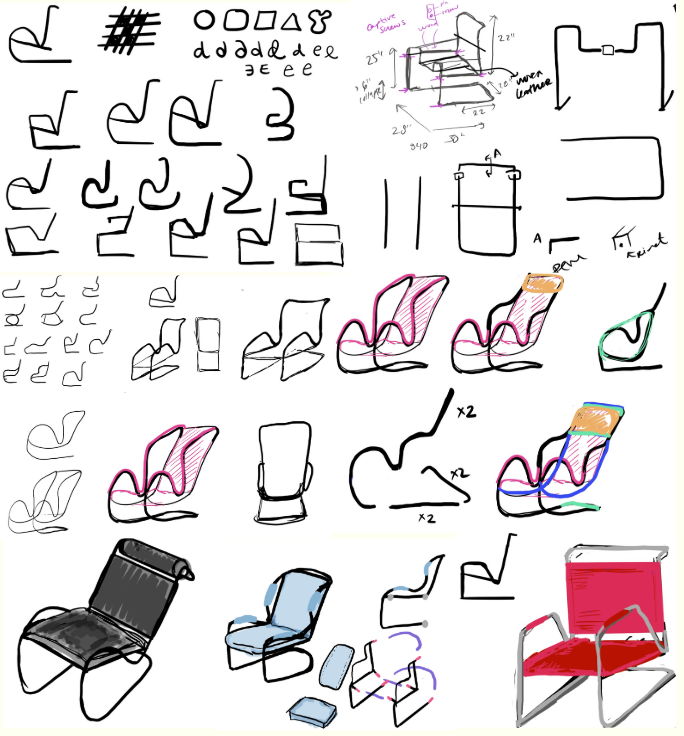

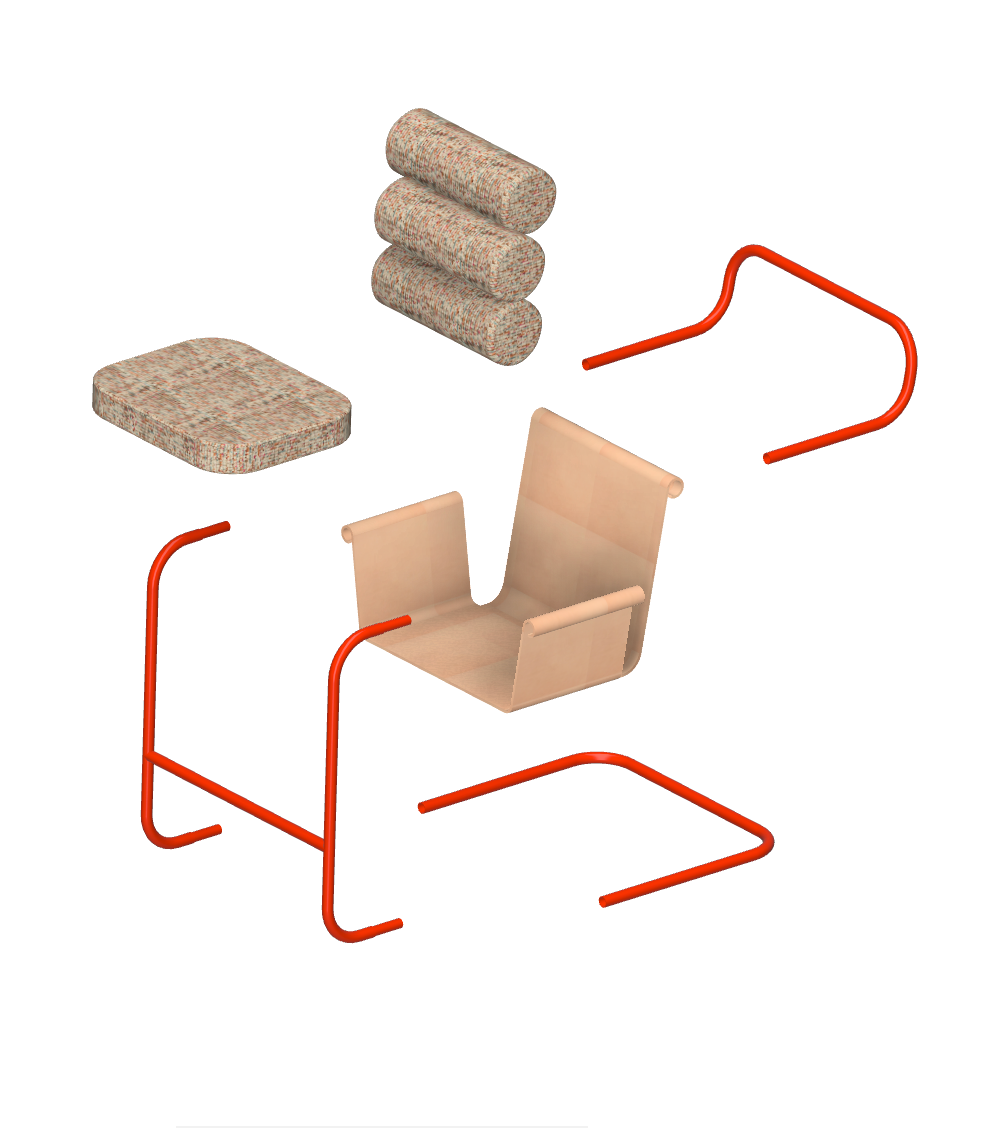

I started brainstorming chair ideas with simple sketches. At first, I limited myself to the size of a post-it note to constrain the amount of detail and time I spent on each design. After initial sketches, I brought my design into CAD so that I could better adjust the proportions and see the design from different angles quickly.

From my sketches and a simple CAD model, I created a rough prototype to test comfort and usability. My proof of concept chair was weight bearing and gave me a better sense of how the chair would feel. From this prototype, I added an extra bend to create a different level of back and armrest and moved away from using the crossbar to support the seat. I intentionally made the canvas seat adjustable with webbing and D-rings so that I could find the perfect seat height.

Once I settled on my design, I iterated on the details. It was important to me to use color to make my chair stand out, and I spent a lot of time iterating on the color palette of my chair.

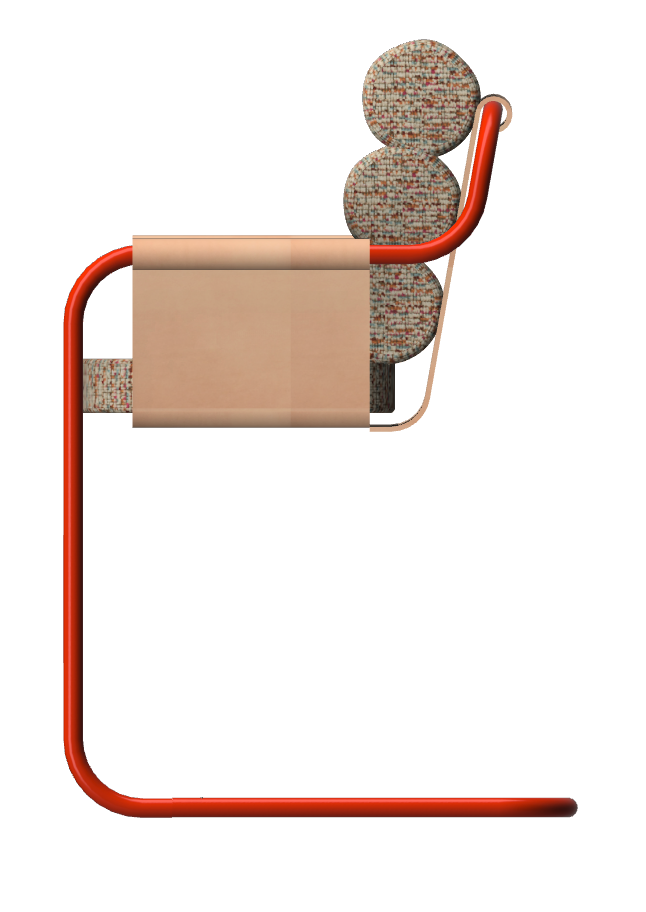

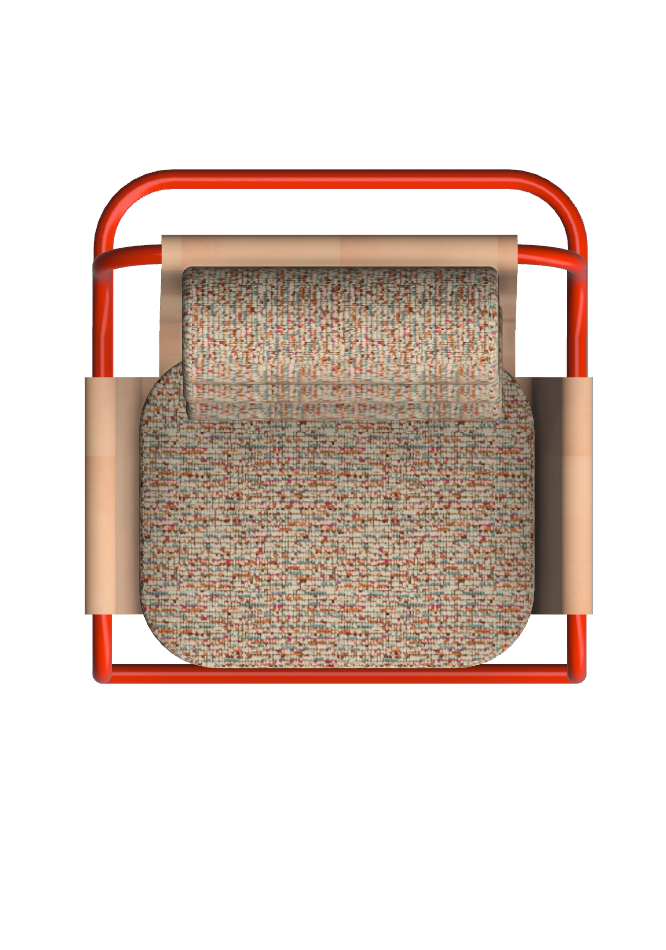

Right: Final CAD Rendering

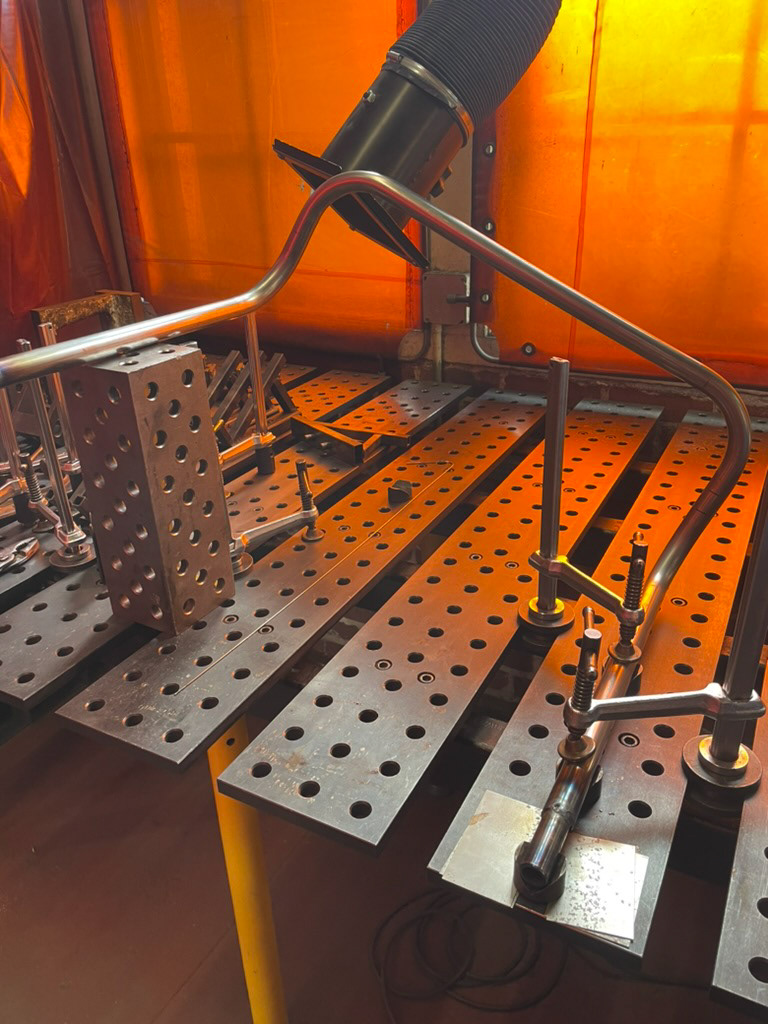

With the design complete and prototype validated, I set off to fabricate my final chair. While I had designed for welded parts at Amazon, this was the first time I was doing the welding myself. I learned a lot of technique as well as patience and appreciation for the craft through building Cirque.

The complete metal involved cutting, bending, and milling tubes and then welding them together. I finished the metal by sanding down the welds and powder coating. I outsourced the powder coating because I did not have an oven big enough to fit my chair.

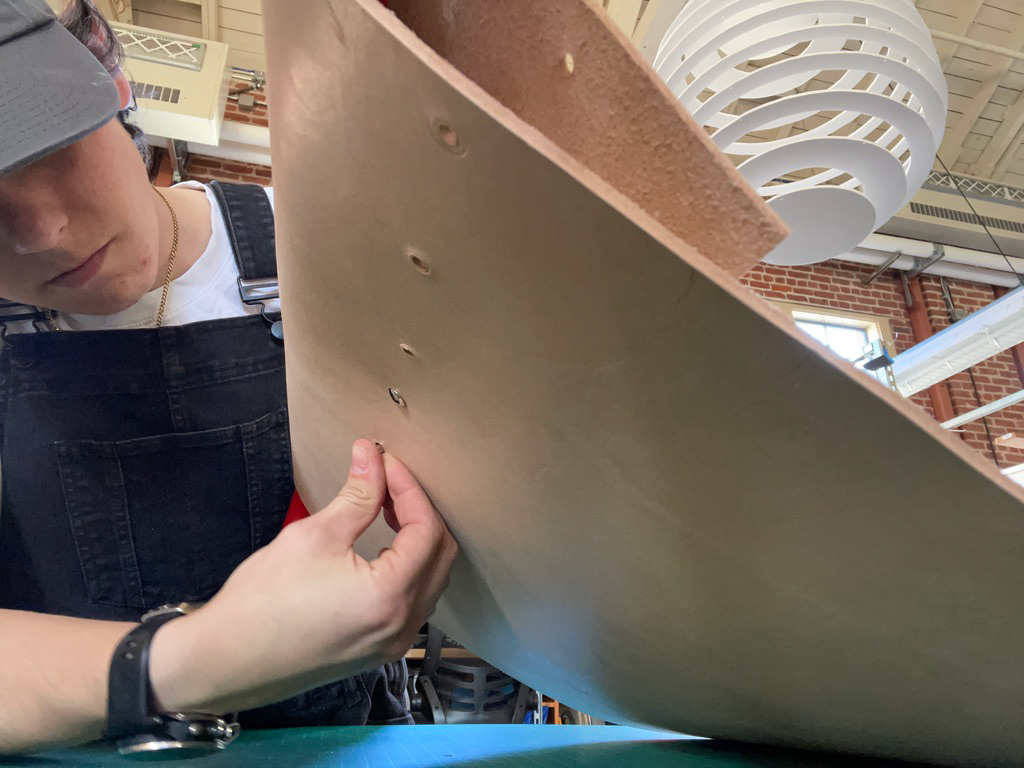

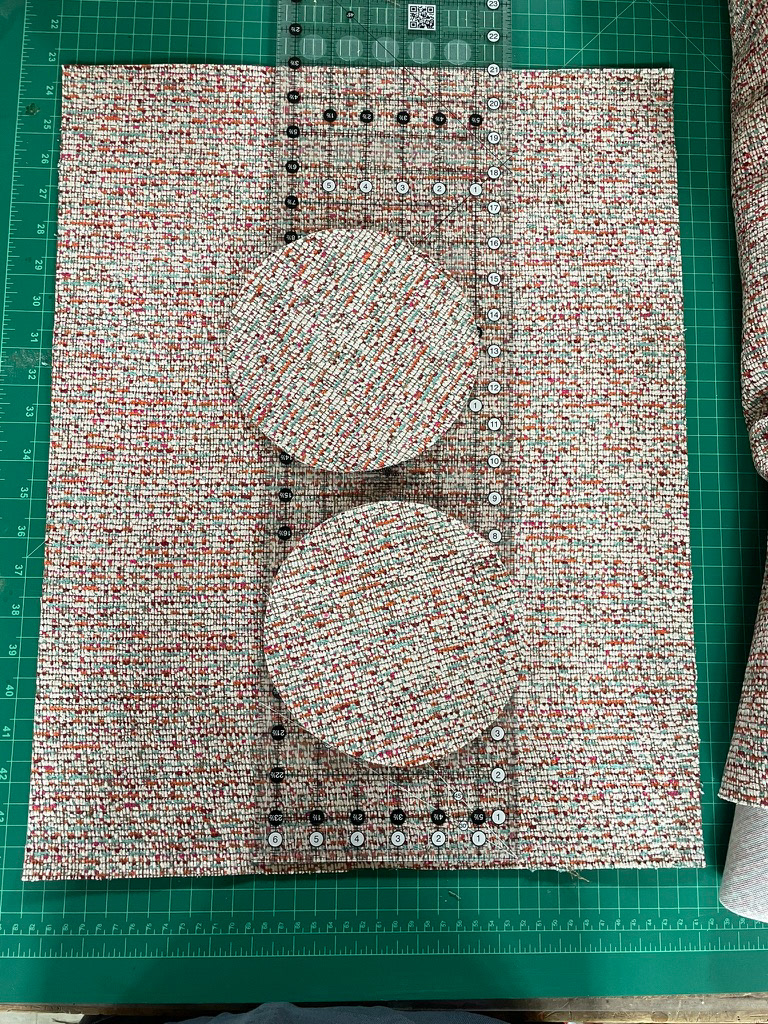

Next up, upholstery and leatherwork! I had never done either before, but I was excited about learning. The seat is upholstered wood and foam, and the back cushions are sewn pillows attached together with a strip of leather. The pillows stay in place with an additional red pipe ballast.

I cut the leather to size based off of my prototype and held pieces together with binding posts. The leather will patina over time.

And lastly, relaxing in my chair!

It has the right amount of movement that I was looking for and I love the red piping. I wanted make a chair that was simple, yet different than anything I’d seen before, and I feel that I succeeded. Reflecting on the process, I realize how much I learned along the way. I had never welded before, so creating a chair that depended on welds was a big endeavor for me. I’m incredibly proud of myself for getting over my fear of welding and practicing so much that I became excited. I knew I had come a long way when rather than holding my breath the whole time, I found myself exclaiming, “ooo that was a good weld,” when I did a nice job.